Classifier vs Segmenter

This page explains the two AI model types available in the OV20i system and helps you choose the right approach for your inspection needs.

Two Types of Projects

The OV20i offers two distinct AI model approaches for different inspection requirements:

- Classification - "Cats vs. Dogs" approach

- Segmentation - "Where's Waldo?" approach

Classification Models

What is Classification?

Create a Classification Recipe to train a deep-learning model to categorize an image into different classes based on its visual characteristics.

The "Cats vs. Dogs" Approach: Classification is best suited for projects where the image can be one of a discrete number of states (e.g., good vs. bad, but with any number of classes).

Classification Training Modes

Classification offers two distinct training approaches:

⚡ Fast Classifier

- Purpose: Quick setup and testing

- Use Case: Rapid prototyping and proof-of-concept

- Speed: Faster training time

- Accuracy: Lower precision

- Production Ready: ❌ Not recommended for production

Accurate/Production Classifier

- Purpose: Production-ready inspections

- Use Case: Final deployment and manufacturing

- Speed: Longer training time

- Accuracy: Higher precision

- Production Ready: ✅ Main training model for best results

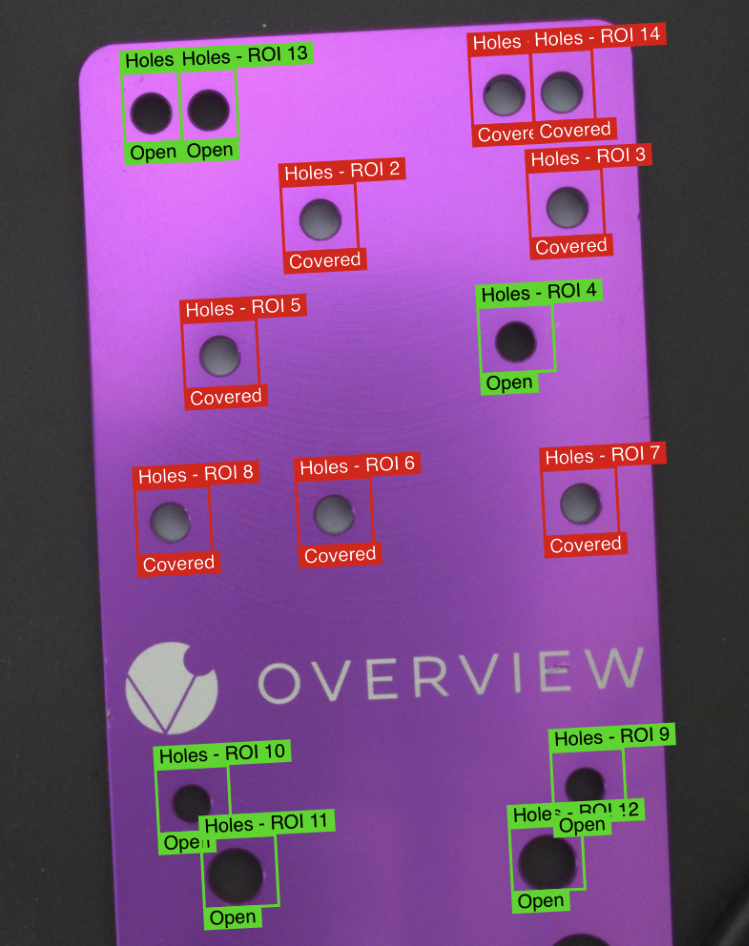

Classification Examples from Production

Example 1: Loose Nut Detection (OEM Assembly)

Task: Identify loose nuts in mechanical assemblies

Setup:

- ROI: Rectangle around nut area

- Classes:

- ✅ Good - Properly tightened nut (Pass 100%)

- ❌ Defect - Loose nut (Fail 98%)

Result: Binary decision - nut is properly seated or loose

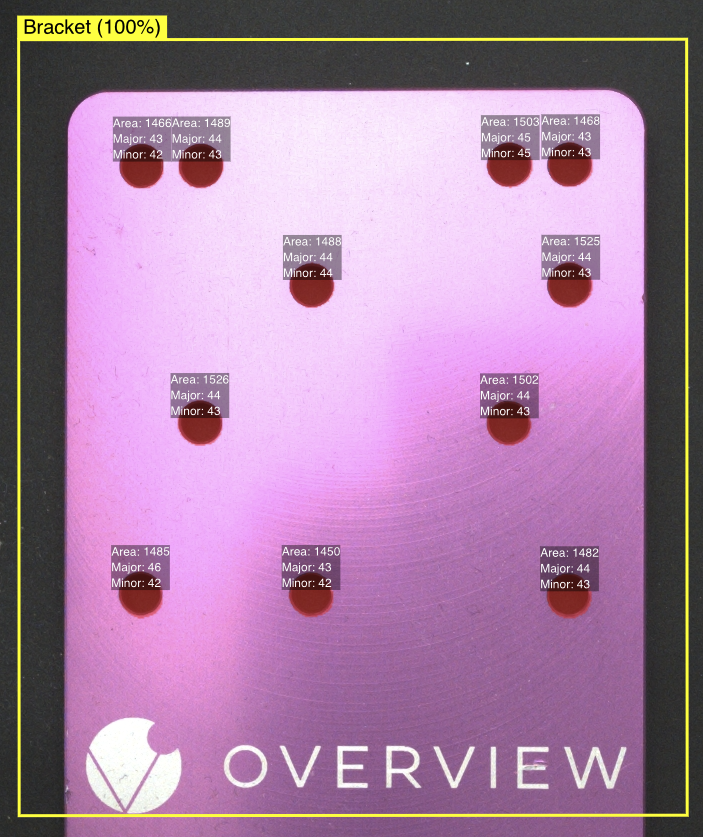

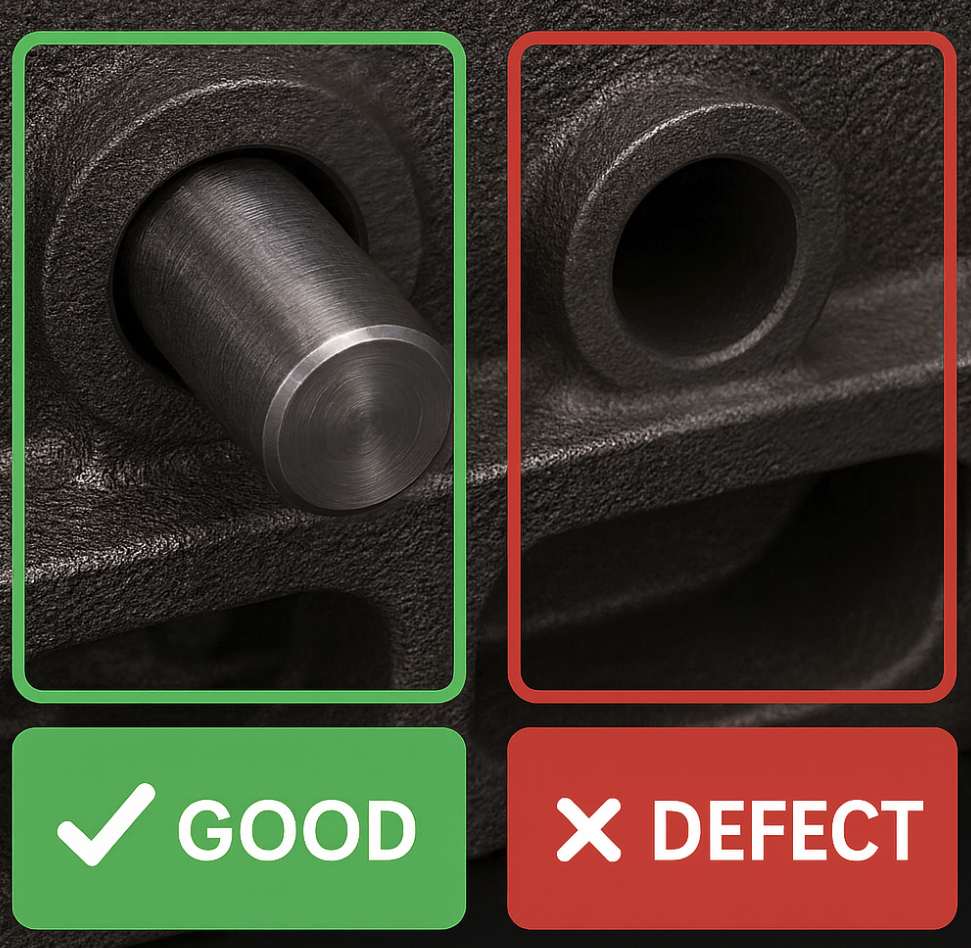

Example 2: Shaft Seating Verification (OEM Assembly)

Task: Identify partially seated shafts

Setup:

- ROI: Rectangle covering shaft mounting area

- Classes:

- ✅ Good - Fully seated shaft

- ❌ Defect - Partially seated shaft

- ❌ Defect - Fully out shaft

Result: Component gets categorized as properly installed or defective

Example 3: Bent Pin Inspection (T1 Supplier Fabrication)

Task: Check for bent Pins

Setup:

- ROI: Rectangle covering radiator pin array

- Classes:

- ✅ Good - Undamaged Pin (Straight)

- ❌ Defect - Bent/Damaged pins (Bent)

Result: Classifier differentiates a good and a bad pin

Segmentation Models

What is Segmentation?

Create a Segmentation Recipe to train a deep-learning model to take an image and segment classes at a pixel level based on labeled defects. By operating at a pixel level, this tool is useful for inspections that need finer-grained control over labels.

The "Where's Waldo?" Approach: Segmentation is best suited for projects where the defect can take a variety of shapes and sizes, but show up in a variety of locations (e.g., looking for scratches and dents).

Segmentation Training Mode

Accurate/Production Only

- Purpose: Production-ready pixel-level analysis

- Training: Single high-accuracy mode

- Speed: Longer training time for precise pixel classification

- Accuracy: High precision for detailed defect mapping

- Production Ready: ✅ Optimized for manufacturing environments

Segmentation Examples from Production

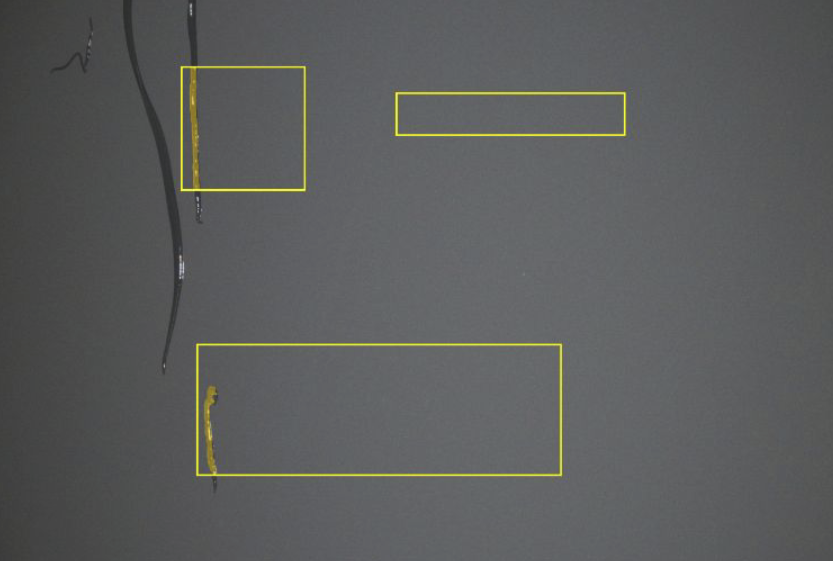

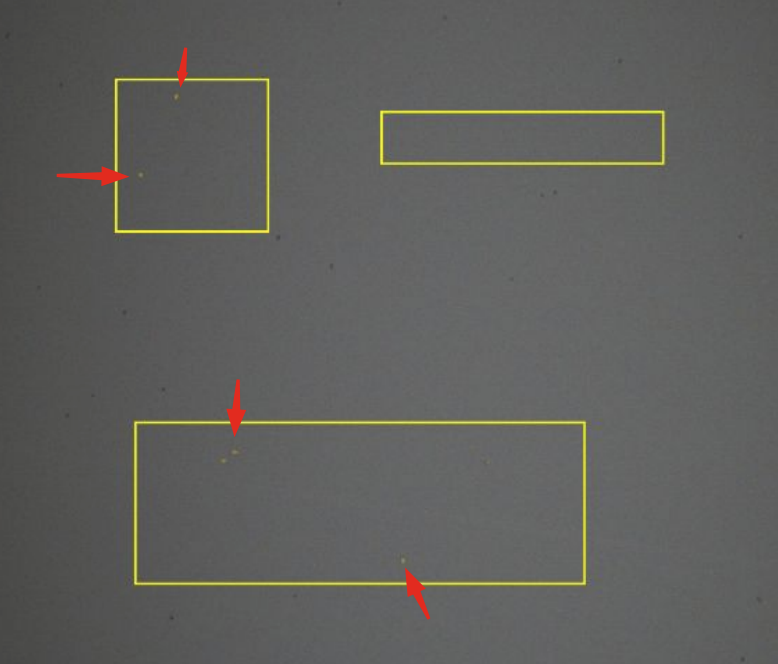

Example 1: Surface Defect Detection (T1 Supplier Assembly)

Task: Identify Glue spill

Setup:

- ROI: Rectangle around valve surface

- Pixel Classes:

- Glue (Yellow pixels)

Result: Yellow highlights show exactly what the AI model detected as defects, with raw images shown for reference

Example 2: Gap Size Measurement (T1 Supplier Assembly)

Task: Verify that the gap of the inspection is the right size

Setup:

- ROI: Rectangle around gap area

- Measurement Logic: Pass condition based on pixel area values

- Classes:

- Blue pixel teaching what distance looks like

- ✅ Good - Area < 100 pixels (Pass)

- ❌ Defect - Area > 100 pixels (Fail)

Result: Precise measurement of gap size with exact pixel count

Example 3: Paint splatter

Task: Identify there is not paint splatter

Setup:

- ROI: Rectangle around the inspection region

- Pixel Classes:

- Yellow pixel to teach what paint looks like

Result: Pixel-level detection of pain splatter

When to Choose Each Model

Choose Classification When:

Discrete State Decisions:

- ✅ You need simple good/bad categorization

- ✅ The entire ROI can be labeled as one of several classes

- ✅ Overall condition assessment is sufficient

- ✅ Fixed defect locations are expected

- ✅ Faster cycle times are acceptable during inspection

Best for: Go/No-Go decisions, component presence/absence, overall quality assessment

Choose Segmentation When:

Variable Location Analysis:

- ✅ Defects can appear anywhere in the inspection area

- ✅ You need to measure size or area of defects

- ✅ Multiple defect types may exist in one image

- ✅ Precise location mapping is required

- ✅ Fastest cycle times are critical for production

Best for: Surface defects, gap measurements, coverage verification, variable-location flaws

Performance Comparison

Cycle Time Performance

| Model Type | Inspection Speed | Best Use Case |

|---|---|---|

| Segmentation | ⚡ Fastest | High-speed production lines |

| Classification (Accurate) | Slower | Quality-critical inspections |

| Classification (Fast) | Medium | Testing and prototyping |

💡 Performance Note: Segmentation models provide the fastest inspection cycle times, making them ideal for high-throughput production environments.

Training Mode Summary

Classification Training Options

- Fast Mode: Quick setup for testing (not production-ready)

- Accurate Mode: Production-ready with higher precision

Segmentation Training Options

- Accurate Mode Only: Single high-precision mode optimized for production